Tired of erratic behavior from your toilet?

You have to hold the handle down because the "flapper" closes too quickly.

You have to jiggle the handle to get the flapper to close at all.

The toilet requires hearing protection when flushed, or sounds like a loud hissing water snake.

The toilet "ghost flushes" about every 2 or 3 hours.

You can of course call the plumber and spend about $200 - $300 to get if fixed, after

a 2 or 4 week delay.

OR: You can fix it yourself for about $40 - $50 bucks, AND clean the toilet and the area around it - the

way you would want it to be cleaned. And maybe even paint the area behind the tank to match your wall color if

you want to.

How hard is it? It's probably a 4 to 5 on the D.I.Y. scale of 1 - 10. The newer plumbing parts all have simple

connections, with rubberized washers that seal by hand-tightening in many cases. Other fasteners require only

minor tightening with a wrench. Leaks are less common with these parts. Final adjustments are vastly simplified as

well.

So give it a try. The tips that I provide in this article should keep you out of trouble.

Do note that this article applies to "standard" toilets, with a separate tank and bowl,

and standard flush and fill mechanisms.

Here's a "Before" picture of a Crane toilet tank in need of an overhaul. Note

the corrosion on the float arm.

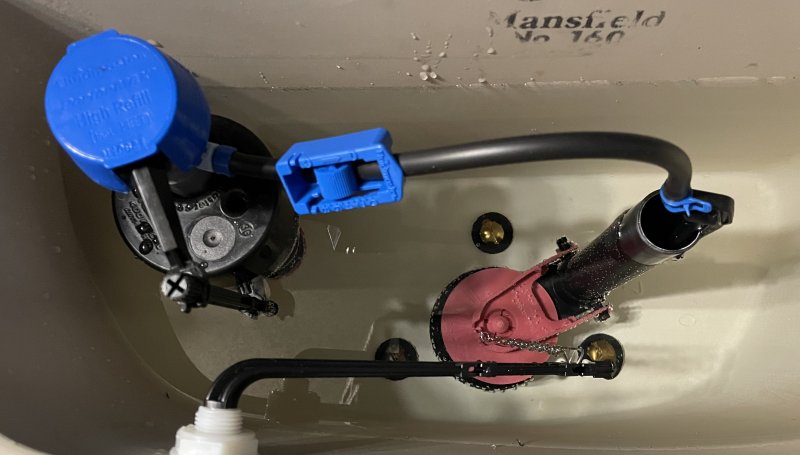

The assembly on the left is called the "Fill Valve". This is the old style valve - the same design

that has been used since the 60s - and it uses a plastic or metal float to shut the water flow off.

The item in the center is the "Flush Valve", whose red flapper is raised by a chain that attaches

to the flush handle. |

1 The first step is to shut off the water

valve at the wall.

But before shutting it off, wipe the shaft with a cloth dampened with a bit of the cleaning spray.

Why? Because the shaft will be covered with dust. When the handle is turned, this shaft will slide past the

shaft seal (often called "packing material"). We don't want the dust/grit to damage this seal.

Also, before turning it off, make sure you know where the house main water shutoff valve

is located! The reason is discussed next. |

|

|

1a First of all, be careful in trying

to turn it too tight! The shutoff valves with the nylon shaft can break! (Applies to both toilet shutoffs

and water faucet shutoffs). This has happened twice to me, even in a relatively modern house -

built in 2007. If this happens, you will have to turn off the main water supply. You aren't totally screwed if

this happens. See steps 1c and 1d for a fix.

So, the shutoff valve may continue to leak when you shut it off. And turning it too tight risks

risks breakage. If it leaks too much, it will be necessary to shut off the main water supply. But also

see steps 1c and 1d.

|

1b Here's another type of supply line.

You will be doing a lot of good to replace this type of line with the newer braided lines. Note that

this shutoff valve actually did what it was supposed to do: successfully shut off the water! (Yes. We live

in an imperfect world. . .) You can ignore the next two sections.

|

|

|

1c Do this sort of thing often?

Maybe you may want to rebuild your neighbor's pots, or those of your parents or in-laws. If so,

these items may be of interest.

Does the water keep dripping, even though you have closed the water valve behind the toilet?

The two parts on the left of this picture will enable you to fix the toilet without shutting off the main

water supply. NOTE: This also applies to the valves that supply the kitchen or bathroom sinks, too.

The upper left is a "3/8 comp cap". Remove the original water supply line and put the cap in its place.

The black part on the lower left: You can make another type of "emergency cap" by cutting off

the bottom of an old fill valve. I did this, and filled the internal cavity with glue and allowed it to

harden. You would just leave the original supply line in place and just screw this "cap" into the white

nut of the original supply line that you see in 1a and 1b above.

Did your valve shaft break on you? The two pieces on the right are replacement shutoff valves.

You can use the shaft/handle part to replace your broken shutoff valve without having to call

a plumber to replace the entire valve.

|

1d This is one of the replacement

parts shown on the right of the previous picture. Just loosen the nut that holds the shaft

and handle in place. You don't need the remaining part on the left. This is the part that would have

been connected to the water supply line. Thus you can buy any type of assembly, whose water supply

line can be any diameter or connection method, as long as it has the shaft/handle part that

matches yours.

Then shut off the main water supply, and remove the nut on the original shutoff valve

(which held the now broken shaft and handle.) Remove the broken part that's still inside - may have

to use a needle nose pliers - or even a flat blade screwdriver. Then screw the

replacement shaft/handle in the original shutoff valve. Now it's good as new (and you didn't have

to call a plumber to go into the wall to replace the entire valve assembly).

|

|

|

2 Step 2 is to remove the

toilet tank bolts. As I mentioned above, this is MUCH easier with a standard wrench (in this

case a 1/2 inch) than trying to use pliers or an adjustable wrench.

|

2a Now you can lift the tank

off and lay it on the old towel. This is a Mansfield tank, and it has 3 bolts.

|

|

|

2b This is a Crane tank,

and it has 2 bolts. Same for a Toto toilet.

|

3 Now remove the old rubber

seal and remove the flush valve nut.

|

|

|

4 Clean the old tank. This one actually

had rust from the original bolts. This is where a scraper will be handy. Some fine sandpaper also helps.

The black stains from the deteriorated rubber washers actually wash off quite easily. Just about any

countertop cleaner or even glass cleaners will work fine.

|

4a Here's the Crane tank all cleaned

up. The stains around the bolt holes are OK, as long as the immediate area around the bolt holes is

free of bumps.

|

|

|

4b And here's the Mansfield

tank all cleaned up. It was much newer than the Crane tank. The white square shaft is part of the

original flush handle assembly.

|

5 Here's your chance to clean

the back side of the toilet bowl itself. Clean underneath as well.

|

|

|

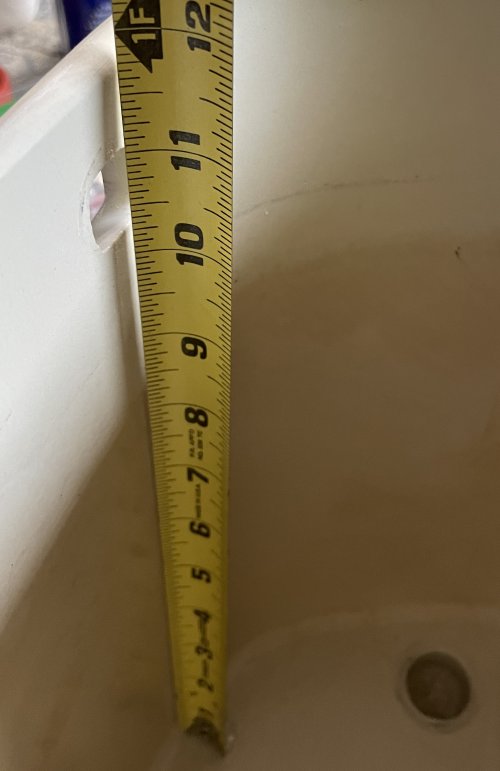

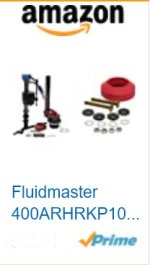

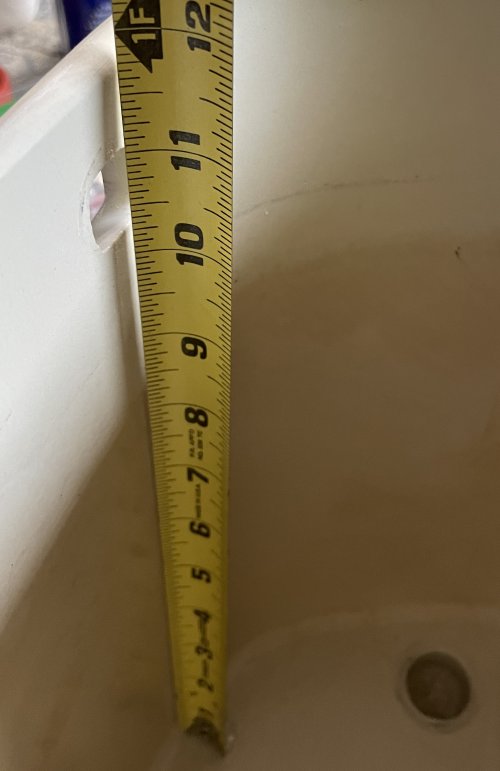

6 Now we want to measure

the height of the flush valve. The latest instructions that come with the Fluidmaster kits are

MUCH clearer! No more "C/L", or "Critical Level" terminology! We simply want to make 3 simple

measurements:

First measure the distance from the bottom of the square flush handle opening

to the bottom of the tank. 10 inches in this case.

We want the top of the flush valve tube to be approximately 1 inch below this.

(next section).

And we want to have the top of the fill valve to be approximately 3 inches from

the top of the flush valve tube. (Sections 9 and 9a)

|

6a So measure from the bottom

of the flush valve's black gasket. I have marked the cutoff point. 9 inches in

this case.

|

|

|

6c If you have the "preferred"

tubing cutter, cut off the excess tubing. Just spin the cutter around the tube, while tightening

the knob a little every few spins.

|

6d A hacksaw works fine, too.

Just smooth off the cut with some sandpaper.

|

|

|

7 Remove the large white nut

from the flush valve, leaving the black rubber washer. Place the flush valve in the tank such

that it does not cover any of the bolt holes. We want the tube to be toward the back, so that the

flapper chain can easily reach the flush handle assembly.

TIP: The chain hook that will connect to the flush handle assembly is secured, for shipping

purposes. Unhook the chain at this point! It will be a lot easier than trying to do this when the

tank is full of water!.

|

7a Here is a good orientation

for tanks with two holes.

|

|

|

7b Lay the tank on its back and attach

the big white mounting nut. Hand tighten and then tighten only about 1/2 turn more with the big

wrench. Because of the improvement in plumbing seals and gaskets, it is no longer necessary to "put

the supertight" on plumbing parts.

|

7c Slide the big rubber tank-to-bowl

gasket in place.

|

|

|

8 Attach and tighten the tank bolts.

Place a black rubber washer on the bolt and slide the bolt through the tank from the inside.

On the bottom side, put a rubber washer followed by a metal washer, and then the nut.

Just loosely hand tighten first. Move the bolt from side to side and feel it contact the ceramic

of the tank. Now try to move it to the center of the hole so that the bolt is not in contact with the ceramic. This

will help reduce the chance of cracking the tank and will help isolate the tank acoustically from the bowl, for less

water noise. Holding the bolt still, bring the nut up and hand tighten. Then use the wrench to tighten it snugly - but

not so tight that the washer is significantly deformed on the inside of the tank.

This picture shows the three bolts and the tank-to-bowl gasket.

|

8a Here's the 2 bolt tank.

NOTE: As you see in this picture, I did not put a rubber washer under the tank. I did this rebuild

several years ago, and indeed the Fluidmaster instructions say to use just the metal washer under the tank.

But I have had this method result in tank leaks in the past. Thus in my opinion it is better to have a rubber

washer on both sides:

You have two chances to stop leakage.

You have an additional washer seal in case the inside of the tank happens to be rough around the

bolt holes due perhaps to remaining material from the original bolds and washers.

By using two washers and keeping the bolt away from the tank ceramic, you are keeping the tank

isolated from the bowl and reducing water noise while the toilet refills. This is called "De-coupling" the tank.

|

|

|

9 Carefully place the tank onto the bowl.

Put a washer and a nut on each bolt and loosely tighten. If you have extra rubber washers, you can use them

as well. In that case, put the rubber washers on first.

Look at the tank from the front to see if it looks level. You can use a level on top, if you have one. Also

make sure the tank isn't resting against the wall. There needs to be room for the tank lid edge to fit between

the tank and the wall. (See "9a" on the right.) Rock the tank a bit while pulling or pushing on it when

making adjustments (bolt nuts should be loose). Then hand tighten the nuts. For the three bolt tank,

tighten the front two first.

Now gently tighten the nuts with the wrench, until the tank is stable. Don't tighten very much. You will

do the final tightening when the tank is full of water (when it's about 20 - 30 pounds heavier!)

|

9a This shows the tank being at least

about 1/2 inch from the wall.

|

|

|

10 Adjusting the fill valve length.

The fill valve is shipped at the lowest height. Lengthen it by grasping the grey shaft (move the float

upward to expose more of the grey part). Grasping the black section, twist the black section to lengthen

the fill valve.

|

10a Place the fill valve in the tank

and measure. As noted above, you want the top of the fill valve to be approximately 3 inches above

the top of the flush valve. The top of the flush valve was 9 inches from the bottom of the tank. So

we add 3 inches for the top of the fill valve. That would be 12 inches, except that the top of the fill

valve is almost even with the top of the tank. So it's11 1/2 inches in this case.

Make sure the rubber washer is on the bottom of the fill valve!

Once the correct height is determined, you can secure the fill valve by attaching the

locknut on the fill valve, under the tank. Hand tighten only. (Make sure the refill line nozzle near the top

is sticking out to the right, toward the interior of the tank.) |

|

|

11 Put a bit of WD-40 or light

oil on the threads of the shutoff valve sticking out from the wall. This makes it much easier to

tighten up the braided line nut without getting it too tight. Connect the braided line and tighten

it until you feel the rubber seal beginning to compress. The newer seals do NOT need much

tightening.

|

11a Now connect the large white

nut of the braided line to the fill valve.

Hand tighten this nut. It is helpful to use a dry rag to help you tighten the nut.

Yes, it looks like a nut. NO!! You should not use a wrench to tighten it further. Hand tightening

with a rag is plenty.

|

|

|

12 Before attaching the refill line,

move the roller first. (The refill line directs some of the water down the flush valve tube

to fill the toilet bowl itself.) If the line is not restricted, too much water will be wasted over-filling the toilet

bowl. The blue assembly clamps the refill line. But you want to move the roller BEFORE attaching

the refill line. Why? Beause it's hard to move the roller!

|

12a Before attaching the black

clip to the refill line, hold the end of the refill line near the top of the flush valve refill tube. You want

an arc, so that the top of the arc is a bit higher than the blue top of the fill valve, but not so much

that the whole refill line is up against the tank lid. Doesn't matter if it touches the lid a bit. Cut off the

excess; it's better to error in having the line too long - not too short!

Push the clip into the refill line and attach it to the flush valve tube. Yes, the clip is "Wierd"!

Push it over the edge of the tube, with the metal part on the outside.

|

|

|